PATEL

Pork Division

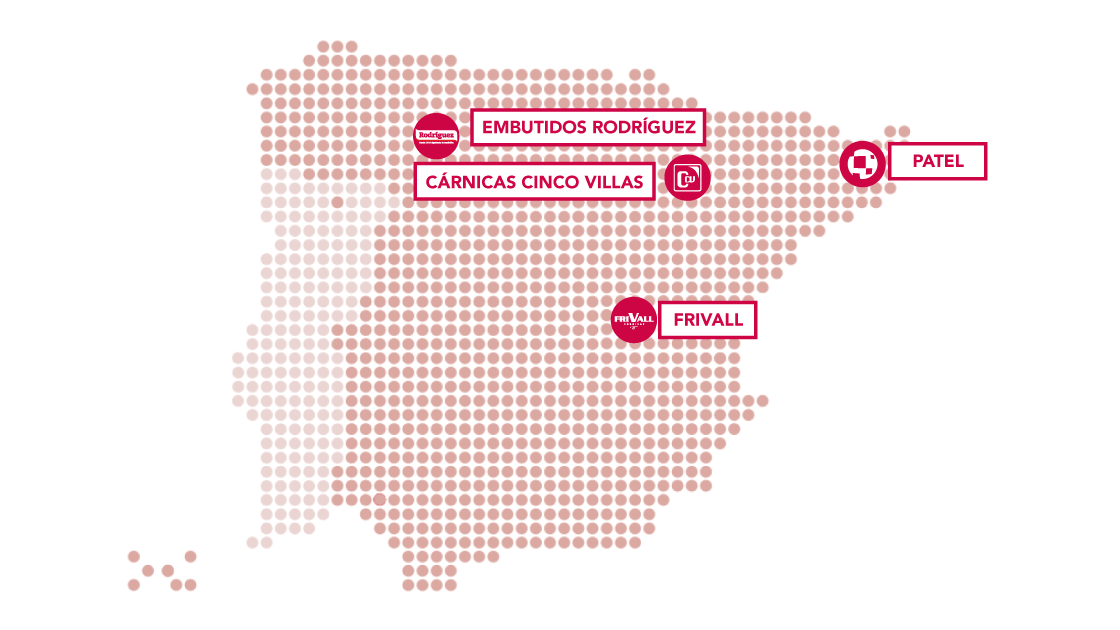

Patel is the trade name of the Vall Companys Group's pork products. It operates four company-owned abattoirs and four cutting rooms, generating more than 300,000 tons of top-quality fresh pork a year, which are exported to the world's most demanding markets.

Production of pork from white pigs by the various group companies stands at over 4.3 million animals per year. Process integration and verticalization ensure a consistently high quality standard in all processes.

MAXIMUM QUALITY FROM THE

SOURCE

VALL COMPANYS GROUP

Vall Companys is a leading Spanish family-owned agri-food group founded in 1956. The Vall Companys Group operational model is based on the integration of all stages of the production process, and the work of dedicated professionals who are highly trained in their respective fields.

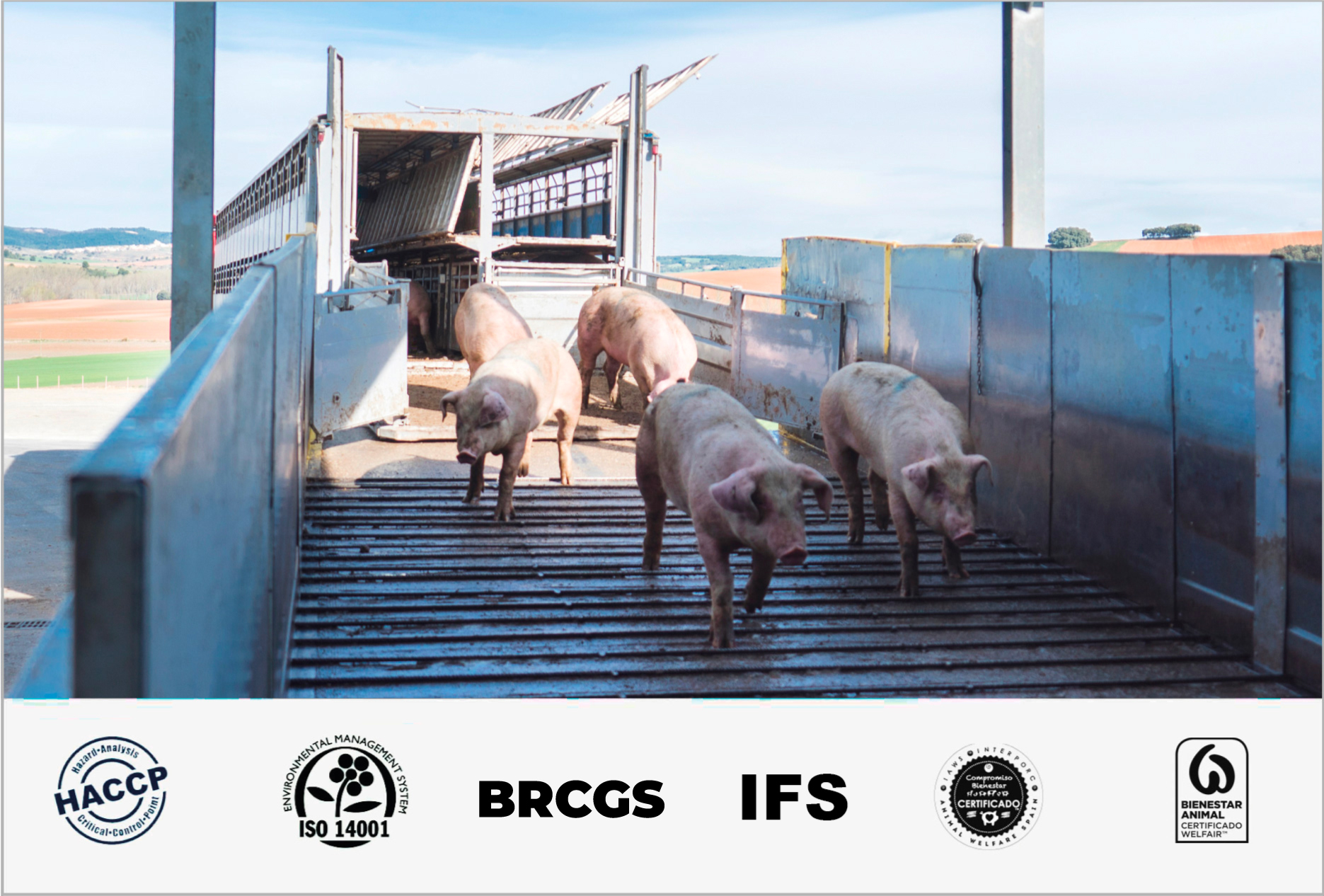

QUALITY ASSURANCE PROGRAMME

Quality and Animal Welfare

Animal welfare is a priority in our abattoirs, and for this reason all necessary measures are put in place to ensure it is respected: optimisation of transport and holding pen times, automated conveyance of animals to the CO2 stunning units, officially approved training for all personnel involved in animal handling and meticulous control of the entire procedure.

The company has Animal Welfare monitoring systems endorsed by various external certifications that annually validate our implemented programmes, ensuring that our animal protection standards go beyond current legislation.

-

Control of all production stages.

-

Control of raw materials:

Certified suppliers and Quality specifications. -

Process control: On-line traceability, HACCP Critical Control Points, ISO 14001, BRCGS, IFS, BBC.

-

Certified, auditable documentation.

-

Quality, Food Safety and Environment Policy.

-

Welfair™ Animal Welfare certification based on the European Welfare Quality standard, for slaughter and traceability in Patel, SAU, and for slaughter in Cárnicas Frivall and Cárnicas Cinco Villas.

-

IAWS - Interporc Animal Welfare certification.

VERTICALIZATION AND TRACEABILITY

Vertical integration system

Patel and its various production plants make up a fully integrated production and marketing

process, covering

all

stages from reproduction, nutrition and animal rearing to slaughter, quartering, packaging

and distribution of

the

end product, as well as all complementary processes (animal health, integrated

logistics, etc.).

This verticalization and integration policy allows full traceability of any product

to source,

and ensures consistent, stable quality throughout the production line.